SCIENTIFIC SCHOOL

Department of “Technical systems and technologies of animal husbandry named after B. Shabelnik”

FOUNDER IS SHABELNIK BORIS

Professor, Honored Worker of Science and Technology of Ukraine,

Doctor of Engineering

(1929 – 2004)

Borys Shabelnyk is an outstanding scientist in the field of agricultural mechanics. He was born on November 9, 1929, in Kharkiv in the family of a worker. He graduated from the Kharkiv Institute of Mechanization and Electrification of Agriculture (1955) and headed the Berdyansk MTS workshop in the Kharkiv region (1956-1957). From 1957 to 1958 he was a mechanical engineer at the MTS department of the Kharkiv Regional Department of Agriculture. From 1959 to 1965 he was an engineer, senior engineer, group leader, and head of the laboratory of the Ukrainian Research Institute of Agricultural Engineering. Then he studied at the graduate school of KIMEA and in 1967 he defended his dissertation “Theoretical and experimental studies of the cam conveyor-cleaner of beet harvesters,” headed the Department of Mechanization of Livestock Farms (1968-1983). He founded a branch research laboratory of energy-saving working bodies of production and harvesting of root crops, was engaged in the development and theoretical substantiation of mechanized means of harvesting fodder beets. At the same time, he worked on the training of highly qualified personnel. Under his supervision, 7 candidate dissertations were prepared and defended.

In 1986 Shabelnyk B. defended his doctoral dissertation on “Development of the technological process and the creation of conveyors – cleaners of beet harvesters”.

The scientist paid special attention to the theoretical and experimental study of conveyors – root crop cleaners, as one of the main working bodies of beet harvesters. In theoretical research, he used original mathematical models that allowed to ensure the practical implementation of developments in production. His proposed design parameters of conveyors – cleaners were widely implemented in production (produced more than 50 thousand machines at the Ternopil combine plant).

The state highly appreciated the active educational and research work of Shabelnyk B., he was awarded the badge “For outstanding achievements in work” and the medal “Veteran of Labor”. For his personal contribution to the training of highly qualified specialists, development, and implementation of scientific achievements in 1992 he was awarded the honorary title of Honored Worker of Science and Technology of Ukraine. In 2000, he was included in the published series “Ukrainian agricultural scientists of the XX century. Scientists in the fields of mechanization, electrification, and reclamation.

Shabelnyk B. published 117 scientific papers and monographs and received 25 copyright certificates for inventions.

Under his leadership, the “Mayak 6” feed shop was built and equipped with the necessary machines. Such laboratories allowed to more closely combine the theory and practice of technological processes of livestock production, to increase the level of practical training of students. For this purpose, a branch of the department at the experimental farm “Kutuzivka” NGO “Plemelita” UAAS was established.

The large-scale and bright figure of the Honored Worker of Science and Technology, talented scientist and teacher Borys Shabelnyk will remain not only in the memory of all who knew him personally but will forever go down in the history of mechanical engineering.

He was a successor of the scientific school of Shabelnyk B. Ph.D., Professor Boyko Ivan (Head of the Department of ITF from 1983 to 2005). He had 148 publications, including 90 scientific and 36 educational and methodological, 3 textbooks edited by him and 6 textbooks co-authored, which are recommended for publication by the Ministry of Education and Science of Ukraine > and 32 copyright certificates and patents. The direction of his research is aimed at creating energy-saving machines for grinding grain feed, their dosing, and mixing. Under his leadership, new designs of grain shredders, dispensers, and mixers of feed ingredients were developed. At the All-Ukrainian competition “Invention of the Year” in 2007 and 2009, the developments were made by Boyko I. and his students were awarded diplomas “The best invention of the year in agriculture”. According to the results of the research, the dissertations were defended by Sementsov Volodymyr, Shchur Taras, Rusalyov Oleksandr, and Merinets Natalia.

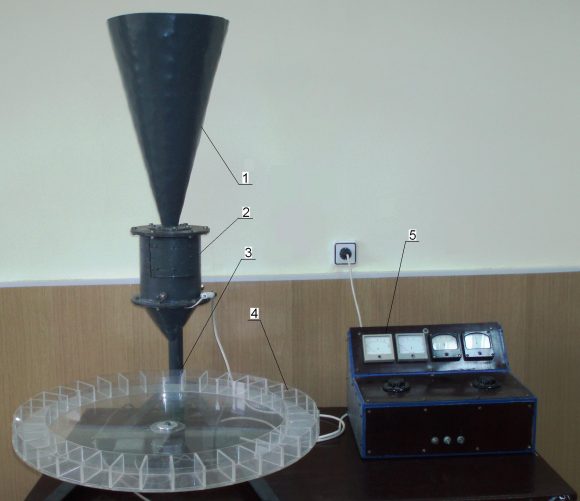

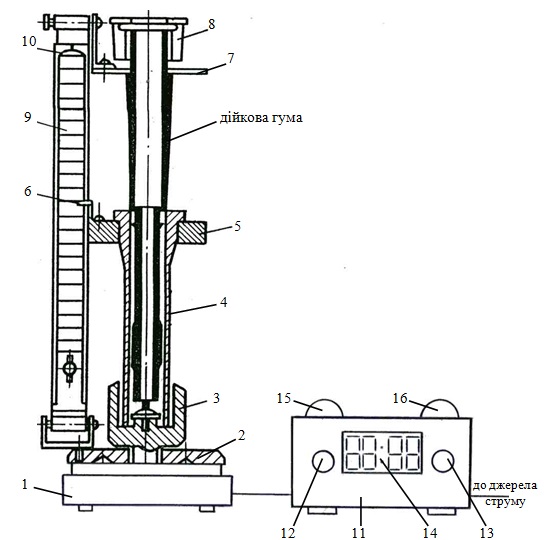

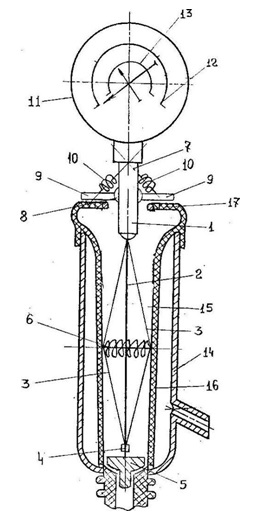

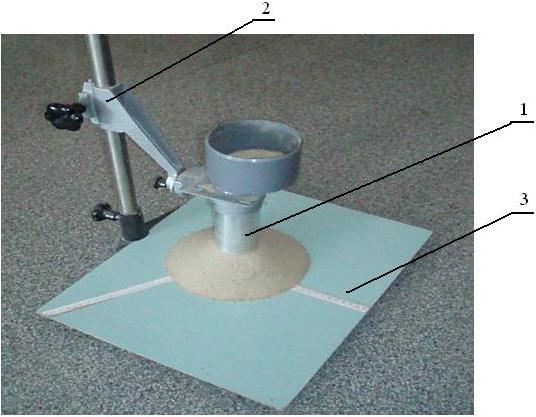

Fig. 1 shows a stand for testing dispensers and mixers of feed ingredients, in Fig. 2 and 3 – dispensers of microelements and compound feeds, respectively. Fig. 4. Unit for preparation of liquid homogeneous feed mixtures from grain.

Professor Boyko I. supervised the post-graduate student Voitov Anton to obtain the degree of Candidate of Technical Sciences.

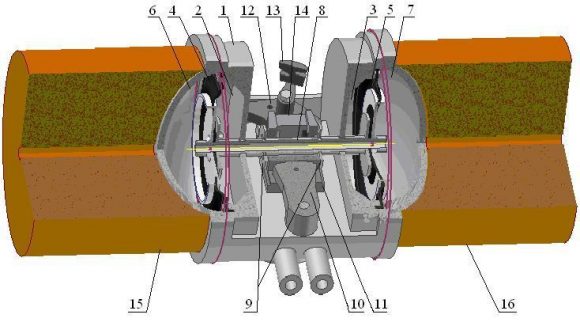

Fig. 1. Unit for feed enrichment (dissertation of Sementsov V.)

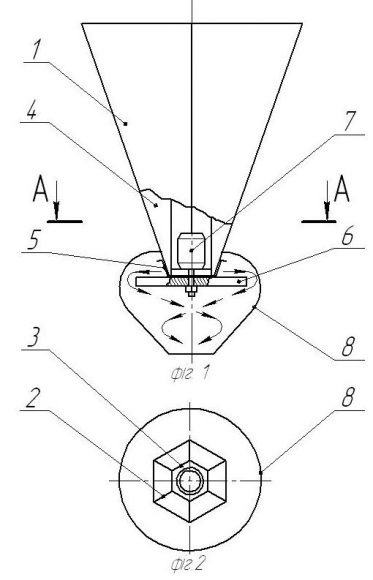

Fig. 2. Experimental installation for research of process of dosing of biologically active forage additives (the dissertation of Shchur T.)

Fig. 3. Installation for dosing of loose materials (dissertation Rusalyov O.)

Fig. 4. The unit for preparation of liquid homogeneous forage mixes from grain (the dissertation Merinets N.)

The second direction of scientific activity of the department “Substantiation of the infrastructure of technical service of machines in animal husbandry, technical and technological problems of production of livestock products” is headed by Professor Naumenko Alexander.

Under his leadership, the concept of technical service of machinery and equipment in animal husbandry was developed. Professor Naumenko OA prepared and published a textbook “Technical service in animal husbandry”, a course of lectures “Fundamentals of dealership”; developed a method of substantiation of the structure of technical centers, prepared and issued “Organizational and technological standards”, which received the “Gold Medal” of the Ministry of Agriculture of Russia.

Alexander was the supervisor of scientific works of young scientists who defended their dissertations and work on pedagogical activities at the Institute of Technical Service KNTUA. These are Tikhonov Oleksandr, Ishchenko Kateryna, and Slavkova Larysa. Scientific activity continues.

Dissertations prepared by the scientific school of the department “ Technical systems and technologies of animal husbandry named after B. Shabelnyk“

№ | Name | Dissertation topic | Supervisor | Year of dissertation defense |

| 1 | Yukhin Henadii | Investigation of the process of cleaning fodder beet from soil with a two-tier cam cleaner | Shabelnyk B. | 1978 |

| 2 | Boiko Ivan | Investigation of the process of dosing bulk feed with a rotary dispenser in the preparation of complete feed mixtures for animal feeding | Shabelnyk B. | 1982 |

| 3 | Martynov Volodymyr | Development of a device for harvesting fodder beet tops | Shabelnyk B. | 1989 |

| 4 | Dziuba Anatolii | Development and creation of a device for extracting fodder beet root crops from soil | Shabelnyk B. | 1988 |

| 5 | Shkurko Tetiana | Improvement of technologies for the use of artificial light and ultraviolet irradiation in the premises for cows | Petrusha Ye. | 1992 |

| 6 | Nanka Oleksandr | Development of a device for transporting fodder beet tops to the body of a vehicle | Shabelnyk B. | 1992 |

| 7 | Hridasov Valentyn | Development of a working body for digging out carrot root crops | Shabelnyk B. | 1996 |

| 8 | Polupanov Viktor | Development of digging – separating device of machine for harvesting fodder beet fodder and substantiation of its parameters | Shabelnyk B. | 2003 |

| 9 | Sementsov Volodymyr | Обґрунтування параметрів процесу збагачення комбикормів біологічно активними кормовими домішками відцентровим змішувачем | Boiko I. | 2008 |

| 10 | Shchur Taras | Substantiation of parameters of the dosing process and development of the design of the cone dispenser of biologically active feed additives | Boiko I. | 2009 |

| 11 | Chyhryn Oleksii | Development and substantiation of constructive – mode parameters of adaptive milking machine for bark | Uzhyk V. | 2010 |

| 12 | Ishchenko Kateryna | Technological methods to increase egg productivity and safety of laying hens by improving the microclimate of poultry houses | Naumenko O. | 2010 |

| 13 | Rusalov Oleksandr | Substantiation of parameters of the dosing process and development of the design of the lattice dispenser of concentrated feeds | Boiko I. | 2010 |

| 14 | Palii Andrii | Improvement of technological methods of machine milking of high-yielding cows on industrial type complexes | Korkh I. | 2012 |

| 15 | Slavkova Larysа | Substantiation of process parameters and development of gravity mixer of concentrated feeds with fat-soluble vitamins | Naumenko O. | 2014 |

| 16 | Merynets Nataliia | Substantiation of process parameters and development of feed unit of liquid homogeneous feed mixtures from grain | Boiko I. | 2015 |

| 17 | Sementsov Vitalii | Substantiation of parameters of the dosing process and development of the design of the premix dispenser | Boiko I. | 2016 |

| 18 | Boiko Denys | Substantiation of process parameters and development of the design of the batcher-mixer of components of compound feeds | Nanka O. | 2016 |

Наукові розробки кафедри ТСТТ

Experimental installation of a gravity dispenser.

Postgraduate student Sementsov V. Supervisor: Professor Boiko I.

Utility model patent № 76318 Ukraine, IPC А01J5 / 00, А01J7 / 00.

Device for defecting and completing milking gums of milking cups / Paliy A., Naumenko O., Paliy A., Korkh I., Golubenko A. – № u201208820; Application 17.07.2012; Publ. 25.12.2012 // Bull. № 24.

Experimental installation for the study of mixers. Postgraduate student Slavkova L. Supervisor prof. Naumenko O.

Centrifugal mixer (Sementsov V., Boiko I., Naumenko O.) (US Pat. No. 6586538; RU №2299092)

Mixer working disk

Experimental installation for the study of dispensers

Spiral-screw batcher (Boiko I., Shchur T.) (Pat. UA №19992)

Device for determining the angles of natural slope of bulk materials

Grain shredder (Merinets N., Dziuba A.) (Pat. UA. №73371)

Lighting regulator (Kulbaba S.) (US Pat. No. 83537)

Hydrostabilized pulsator (Chigrin O.) (US Pat. No. 322328110)

Sieve batcher (Boiko I., Rusalyov O.) (Pat. UA №89003)

1 – storage hopper; 2 – partitions of the bunker; 3 – prismatic tube; 4 – hoppers of ingredients; 5 – hopper valves; 6 – rotating disk; 7 – electric motor; 8 – unloading casing

Authors: Boiko D., Naumenko O., Nanka O.