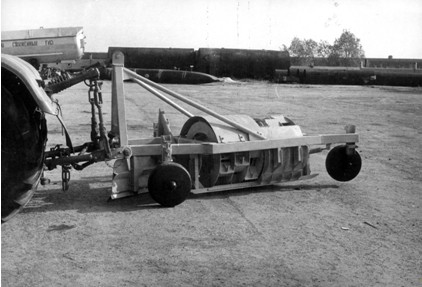

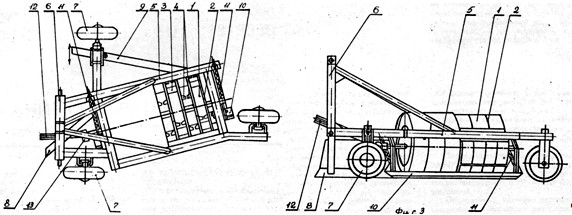

The spreader of organic fertilizers contains a spreading working body in the form of a drum 1 with disks 2, between which are rigidly attached blades 3 and knives 4; frame 5 with hitch 6 and support wheels 7 with height adjustment mechanism, front 8 and adjustable spring-loaded side 9 shields, spring-loaded plate 10 with springs 11 and guide shields forming upper and lower ejection windows, cardan gear 12 with safety clutch 13.

The spreader works this way. During the movement of the unit formed by the swather roller enters the spreader in the capture zone of the front 8 and side 9 boards, after which the fertilizer enters the working area of the drum 1 and the side board 9. Knives 4 grind fertilizers, interactions with the spring-loaded plate are transferred to its edge, after which their ascent begins in the desired direction.

In the event of foreign objects (stones and the like) between the drum 1 and the spring-loaded plate 10, the latter is deflected and into the gap formed passes foreign objects without damaging the working bodies. The presence of disks 2 on the drum 1 contributes to the fact that large foreign objects can not be completely captured by the blades.

Technical performance of the spreader:

- productivity per hour of main time, hа/h 3,5…9,0;

- grip width, m 30;

- working speed, km/h 2,5…7,0;

- application dose, t/hа 10…80;

- uneven distribution of fertilizers, % 22;

- aggregated by class tractors 3,0; 5,0.

Author’s certificates № 1813330; 1741637; 1531884

Authors of development:Ph.D. Makieiev N., Ph.D. Anikieiev O., Sen. Lect. Romanashenko O., Sen. Lect. Krasnorutskyi O.