Laboratory for repair of basic machine parts

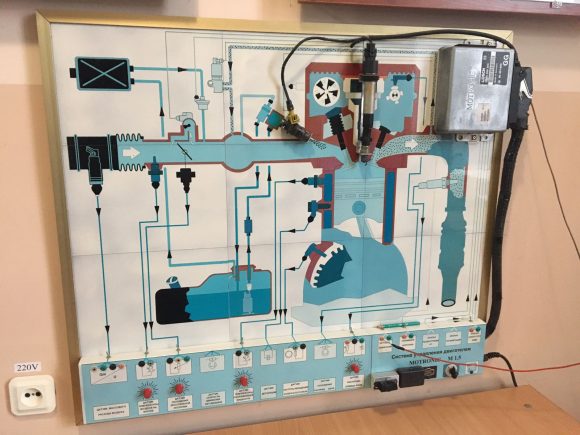

MOTRONIC M 1.5 engine control model

Plasma installation. Electrolytic augmentation of parts. Hydrogen welding.

Crankshaft grinding and plastic surface treatment of parts (vibro-rolling)

Plasma and mycoplasma installations for restoration of details

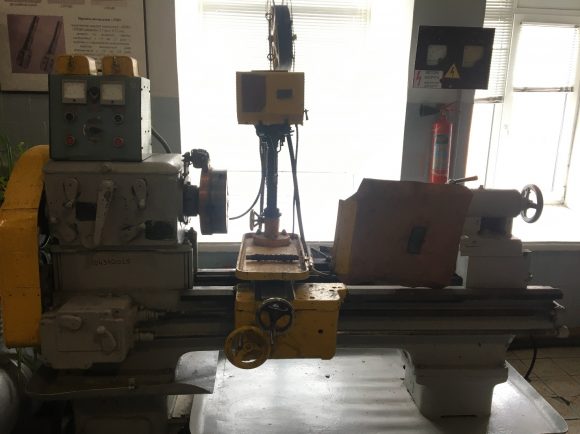

Laboratory of mechanical processing of details

Repair of the gas-distributing mechanism of engines. Boring of cylinder liners. Grinding of restored surfaces.

Repair of the gas-distributing mechanism of engines. Boring of cylinder liners. Grinding of restored surfaces

Laboratory of gas-thermal recovery

Gas-plasma spraying of materials. Gas-flame surfacing and surface treatment. Fusible electrode welding

Welding with a non-fusible electrode. Sandblasting of details

Defective laboratory and wear resistance tests

Disassembly and assembly of rubber wheels of vehicles.

Defectation of parts by ultrasonic and magnetic flaw detection.

Investigation of the process of friction surface wear

Laboratory for repair of components and units

Repair, testing and adjustment of starters, generators and relay regulators

Equipment for disassembly and assembly of vehicle engines

Workplace for repair, assembly and disassembly of the connecting rod-piston group

Repair and testing of hydraulic system components

Repair and testing of oil pumps for internal combustion engines

Repair, testing and adjustment of fuel pumps of diesel engines

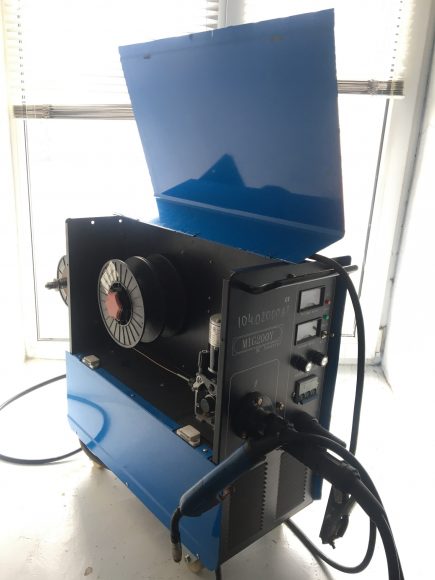

Welding and surfacing laboratory

Restoration of details under a layer of flux

Vibroarc workbench for restoration of details

Restoration of details in the environment of protective gases

Semi-automatic welding of thin-walled parts in CO2

Electrospark restoration of details

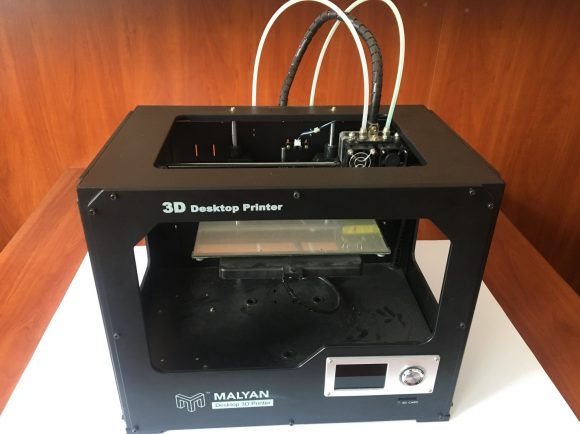

Laboratory of computer-adapted technologies

Production of details by means of the 3D printer

Laboratory of metaphysical research

Metallographic microscope MIM-8

Devices for determining the hardness of materials

X-ray spectroscope and installation for spectral analysis of materials