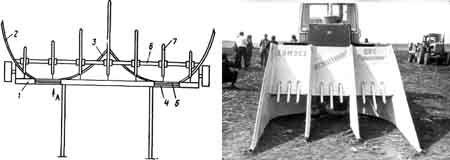

The purpose of the design – the quality of the formation of the roll and increase productivity. As the unit moves fingers 7 pull a pile of dormice off the ground and lift it onto themselves . After that, the fertilizers alternately from go from the fingers and with the help of forming boards 2 are sent to the dosing window 4. Fertilizers that have fallen everywhere fingers in the middle part of the bilateral dump are shifted < span lang = "UK"> divider 3 in side. The parameters of the roll are regulated by measuring the installation height of the fingers 7 and the valves 5.

The roller comprises a frame 1, concave forming boards 2, installed at an angle to the direction of movement, a wedge-shaped divider 3 and dosing windows 4, the height of which is regulated by gates 5. Between forming forms 2 is a transverse beam 6 height, pitch and angle of the fingers 7, The surface formed by the fingers has the shape of a bilateral blade.

During the movement of the unit, the fingers 7, in turn penetrating the pile, pull it off the ground and lift it on itself. As the unit moves, the fertilizers alternately come off the fingers (starting from the extremes) and with the help of forming boards 2 move to the dosing window, and failed through the fingers in the middle part of the two-sided dump fertilizer is pushed aside by the divider 3 to the side. The parameters of the roll are regulated by changing the height of the fingers 7 and the valves. 5.

The formation of two rolls on the edges of the tractor improves the operating conditions of the unit, which eliminates the additional operation of dividing the roll into two streams, resulting in reduced energy consumption.